Categories

- TRANSMISSION-LINE

- Transmission-Line Fittings

- String Hardware

- Tower Attachment

- Parallel Groove Clamp

- Suspension Clamps

- Tension Clamps

- Compression Joint

- Repair Sleeve

- Preformed Armour Rod

- Stockbridge Damper

- Spacer & Spacer Damper

- Arcing Devices

- Counterweight & Jumper weight

- Danger plate & Number plate

- Corona & Grading Rings

- Transmission Conductor

- All aluminium stranded conductors(AAC)

- Aluminium conductors steel reinforced(ACSR)

- All aluminium alloy conductors(AAAC)

- Aluminium alloy conductors steel reinforced(AACSR)

- Arial Earth Wire & Shield Wire & Galvanized Steel Wire

- Porcelain Disc Suspension Insulators

- Composite Long Rod Insulators

- Toughened Glass Disc Insulator

- Tower of Transmission-Line

- SUBSTATION

- Connector and Fittings for Tubular Busbar

- Tubular Busbar Palm(Welding)

- Busbar A-Frame

- Connector for Tubular Busbar

- Tubular Busbar Support

- Tubular Busbar Earthing

- Tubular Busbar End Caps & Balls

- Substation Insulators

- Solid Porcelain Post Insulators(66kV -500kV)

- Solid Polymer Post Insulators(66kV-500kV)

- Hollow Core Insulators for Voltage Transformer

- Hollow Core Insulators for Capacitor

- Porcelain Disc Insualtors

- Polymer Long Rod Insulators

- Glass Disc Insulators

- Busbar

- Tubular Copper Busbar

- Rectangular Aluminum Busbar

- Rectangular Copper Busbar

- Tubular Aluminum Busbar

- Terminations & Connections for Conductor

- Aluminium Flexible Connector

- Copper Flexible Connector(Flat Braid)

- Compression Run Compression T Clamp(Closed)

- Compression Run Compression T Clamp(Open)

- Compression Run Palm Tap(Closed)

- Compression Run Palm Tap(Open)

- Compression Terminal Clamp

- Twin Conductor Compression Terminal Clamp

- Straight Bolted Type Terminal Clamp

- 90° Bolted Type Terminal Clamp

- Straight Twin Conductor Bolted Type Terminal Clamp

- 90° Twin Conductor Bolted Type Terminal Clamp

- Twin Conductor Bolted Type Tee Clamp

- Twin Conductor Run Palm Tap Lengthways Terminal Clamp

- Twin Conductor Run Palm Tap Transverse Terminal Clamp

- Parallel Groove Clamp

- Straight Connector Conductor to Conductor

- Tee Connector Conductor to Conductor

- Adaptor Plates

- Straight Type

- Right Angle Horizontal Type

- Right Angle Vertical Type

- Bi-Metallic Transition Plate

- Spacers

- Galvanized & Stainless Steel Bolts Assemblies

- Strings Fittings

- Connections for Flat Busbar

- Gantries & Structure

- Distribution Conductor

- All Aluminium Stranded Conductors(AAC)

- All Aluminium Alloy Conductors(AAAC)

- Substation Parallel Spacer Triple

- DISTRIBUTION

- Preformed Fittings

- Armor-Grip Suspension Clamp

- Trunnion Armor-Grip Clamp

- Aluminum Alloy Dead-Ends

- Copper Alloy Dead-End

- Thimbles

- Top Ties

- Armored Rod Twin Ties

- Side & Spool Ties

- Parrot Bill End Aluminum Alloy Armor Rods

- Copper Alloy Armor Rods

- Galvanized Steel Armor Rods

- Aluminium Alloy Line Splice

- Copper Alloy Line Splices

- Galvanized Steel Line Splices

- Aluminium Alloy Full Tension Line Splice

- T-Connector

- Helical Arcing Horn

- Galvanized Steel Guy-Grip

- Pole Top Make Off

- Insulated Stay

- Double-Wrap Guy-Grip

- Spiral Vibration Damper High Impact PVC

- Lashing Rods

- PVC Spacer

- The Pole Line Hardware

- Cross Arms

- Fastenes Bolts & Nuts

- Thimble Bolt Rod & Eye Bolt

- Eye Nuts

- Clevis

- Insulation Pin & Studs & Spindles

- Pole Hoop

- Cable & Conductor

- ACSR

- AAC

- ABC Cable

- SAC Cable

- Distribution Insulators

- Porcelain Disc Insualtors

- Polymer Long Rod Insulators

- Glass Disc Insulators

- Porcelain Line Post Insulators(Vertical)

- Porcelain Line Post Insulators(Horizontal)

- Polymer Line Post Insulators(Vertical)

- Polymer Line Post Insulators(Horizontal)

- Porcelain Pin Insulator(BS standard)

- Porcelain Pin Insulator(ANSI standard)

- Polymer Pin Insulators

- Shackle Insulators

- Spool Insulators

- Stay Insulators

- Wiring Insulators

- Telephone Lines Insulators

- Guy Strain Insulators

- Spindle for insulators

- BS Spindle for Pin Insulators

- ANSI Spindle for Pin Insulators

- Normal Short Spindle for Line Post Insulators

- Rachet short spindle for line post insulators

- Rachet long spindle for line post insulators

- Fuse/fuse cutout

- Porcelain Fuse Cutout

- Composite Fuse Cutout

- K Type Fuse Link

- HRC Fuse

- J Type Fuse

- Disconnect Switch

- Surge Arrestor 11-36kV(5kA-10kA)

- Over head Line fittings

- Suspension Clamp

- Bolt Type Tensioning Clamp

- U-Bolts

- Shackle

- Ball Eye

- Socket Tongue

- Arcing Horn

- UT Connectors

- ABC fittings

- Copper Strand Wire and Braid Connector

- Insulation Piercing Connector(IPC)

- Fire-Retardant IPC

- T connecting Terminal

- Insulation Piercing Grounding Connectors

- Fuse Bace

- Wedged Insulation Strain Clamp

- Suspension Clamp for ABC cable

- Suspension Clamp with Aluminum Bracket

- Anchoring Clamp

- Metal Anchor Clamp

- Four-Core Tension Clamp

- Pre-Insulated Sleeve

- Pre-Insulated Bimetal Sleave

- Expansion Screws

- JXL Series Clamp(Wedge Type)

- Parallel Groove Clamp with Insulator Cover

- SAC fittings

- Anti Sway Bracket for HDPE Spacer

- Tangent Support Bracket

- HT Tape for SAC Cable

- Cable lug

- Copper Cable Lugs-DT

- Double Holes Copper Cable lugs-DT2

- Aluminum Cable Lugs-DL

- Double holes Aluminum Cable lugs-DL2

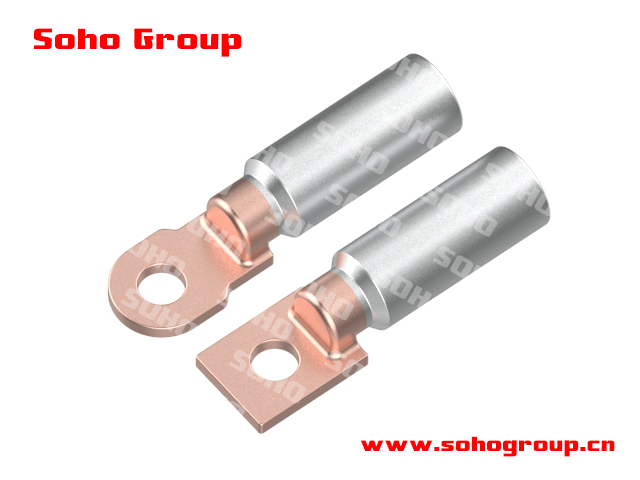

- Bi-Metal Cable Lugs-DTL

- Copper Aluminum Cable lugs-CAL-A

- Copper Aluminum Cable lugs-CAL-B

- Copper Aluminum Cable lugs-European style

- Copper Aluminum Cable lugs-For cable tap box

- Copper Cable Lugs-OT

- P.G. Clamp & Connector

- Copper Parallel Groove Clamp-CAPG

- Aluminum Parallel Groove Clamp-CAPG

- Copper Parallel Groove Clamp

- Aluminum Parallel Groove Clamp-JB

- Copper-Aluminum Parallel Groove Clamp-CAPG(Hard-Solder)

- Copper-Aluminum Parallel Groove Clamp-CAPG( Friction Welding)

- C Clamp-Copper

- C Clamp-Aluminum

- Connecting Clamp-Aluminum

- Connecting Clamp-Copper

- Connecting Clamp (Hard-Solder)

- Connecting Clamp (Friction Welding)

- Connecting Tube-Aluminum

- Connecting Tube-Copper

- Connecting Tube-Bimetal

- Copper Plate

- Aluminum Plate

- Bimetal Plate

- Copper-Aluminum Parallel Groove Clamp( Friction Welding)

- Stay complete set

- Eye Bolts

- Turn Buckle

- Thimble

- Stay Grip

- Stay Wire

- Adjustable Stay Rod

- Non Adjustable Stay Rod

- Stay Anchor Plate/Earth Plate

- Other accessory

- Stainless Steel with Retaining Buckle

- Cable Nail

- Insulation Tape

- Stainless Steel Strip

- Aluminium Insulated Tie Wire

- COMMUNICATION

- Dead-End for OPGW

- Single Suspension Set

- Double Suspension Set

- Vibration Damper

- Armour Rods for Vibration Damper

- Ground Wire Set

- Joint Box

- Cable Tray

- Spiral Vibration Damper

- Corona Coil

- Downlead

- Downlead

- Fastened Fittings for Pole

- Fastened Fittings for Pole

- Fastened Fittings for Twoer

- Fastened Fittings for Twoer

- Fastened Fittings for Twoer

- GROUNDING SYSTEM

- Earth Rod

- Solid Stainless Steel Earth Rods

- Solid Copper Earth Rods

- Copper Clad Steel Earth Rods

- H.D.G Steel Earth Rods

- Earthing Wire

- Copper Wire

- PVC Covered Copper Wire

- Flexible Copper Braid

- Copper Clad Steel Wire

- Fittings for Earth Rod

- Fittings for Threaded Earth Rod

- Fittings for Unthreaded Earth Rods

- Earth Tube

- Conductor Tape

- Copper Tape

- Tinned Copper Tape

- PVC Insulated Copper Tape

- Stainless Steel Tape

- Aluminum Tape

- Bentonite

- Concrete Earth Pits

- Connectors

- C connectors

- Tinned Copper Flexible Connector

- Tape Clip

- Tape Clamp

- Rod to Tape Clamp

- Rod to Cable Clamp

- U-Bolt Rod Clamp

- Earth Points

- Earth Plates

- Solid Copper Earth Plates

- Lattice Copper Earth Plates

- Earth Bars & Disconnector Links

- Exothermic Welding

- Exothermic Powder

- Tooling Box

- Exothermic Welding Mould

- Marconite

- INSULATOR FITTINGS

- Clevis Fittings

- Y-Clevis Fittings

- Tongue Fittings

- Socket Fittings

- Ball Fittings

- Eye Fittings

- For Line Post Insulator

- For Cross-Arm Composite Insulator

- For Pin Insulator

- For Railway Insulator

- For Clamp (Vertical)

- For Clamp (Horizontal)

- Ball Pin & Socket Cap

- Tongue Pin & Clevis Cap

- For Others

- Top Head Fitting for Line Post Insulator

- Top Head Fitting Clevis for Line Post Insulator

- Top Head fitting Tongue for Line Post Insulator

- POWER CONSTRUCTION TOOLS

- Galvanized Steel Antitwist Wire Rope

- Hydraulic Press

- Hand Hydraulic Crimping Tools

- Cable Cutter

- Tube Terminal Crimping Tools

- Mechanical Cable Cutter

- Wire Grip

- Hand Puller

- Snactch Block

- Stringing Block

- Cable Wellhead Pulley

- Cable Orifice Protection Pulleys

- High Voltage Operating Rod/Hot Stick

- H.V. Earthing Wire and Rod

- Security Clamp

- Wood Pole Climber

- Grounding Clamp

- Hot Line Cable Clamp

- Swivel Joints

- Elelctro Scope

- OEM/ODM

- SOLAR

Cable lug

Cable lug

-

Copper Cable Lugs-DT

Copper Cable Lugs-DTMaterial: Copper cable lugs are made of high-conductivity copper or copper alloy, which is an excellent conductor of electricity. This material ensures low electrical resistance and efficient electrical transfer.

Types: Copper cable lugs come in various types, including ring lugs, spade lugs, pin lugs, and butt splice lugs, each designed for specific applications and connection methods.

Sizing: Copper cable lugs are available in a wide range of sizes to accommodate different conductor diameters and configurations. Proper sizing is crucial to ensure a secure and reliable connection.

Termination: The lugs are typically crimped or soldered onto the copper conductor. Crimping involves using a specialized crimping tool to compress the lug onto the conductor, creating a secure and gas-tight connection.

-

Double Holes Copper Cable lugs-DT2

Double Holes Copper Cable lugs-DT2● Material: Copper cable lugs are made of high-conductivity copper or copper alloy, which is an excellent conductor of electricity. This material ensures low electrical resistance and efficient electrical transfer.

● Types: Copper cable lugs come in various types, including ring lugs, spade lugs, pin lugs, and butt splice lugs, each designed for specific applications and connection methods.

● Sizing: Copper cable lugs are available in a wide range of sizes to accommodate different conductor diameters and configurations. Proper sizing is crucial to ensure a secure and reliable connection.

● Termination: The lugs are typically crimped or soldered onto the copper conductor. Crimping involves using a specialized crimping tool to compress the lug onto the conductor, creating a secure and gas-tight connection.

-

Aluminum Cable Lugs-DL

Aluminum Cable Lugs-DL● Material: Aluminum cable lugs are made from high-quality aluminum or aluminum alloy, which is chosen for its excellent electrical conductivity, lightweight properties, and resistance to corrosion.

● Types: Aluminum cable lugs come in various types and styles, including ring lugs, spade lugs, pin lugs, and butt splice lugs, each designed for specific applications and connection methods.

● Sizing: They are available in various sizes to accommodate different conductor diameters and configurations, ensuring a proper and secure connection.

● Termination: Similar to copper cable lugs, aluminum cable lugs are typically crimped onto the aluminum conductor using a specialized crimping tool. The crimping process involves applying mechanical pressure to create a gas-tight connection.

-

Double holes Aluminum Cable lugs-DL2

Double holes Aluminum Cable lugs-DL2● Material: Aluminum cable lugs are made from high-quality aluminum or aluminum alloy, which is chosen for its excellent electrical conductivity, lightweight properties, and resistance to corrosion.

● Types: Aluminum cable lugs come in various types and styles, including ring lugs, spade lugs, pin lugs, and butt splice lugs, each designed for specific applications and connection methods.

● Sizing: They are available in various sizes to accommodate different conductor diameters and configurations, ensuring a proper and secure connection.

● Termination: Similar to copper cable lugs, aluminum cable lugs are typically crimped onto the aluminum conductor using a specialized crimping tool. The crimping process involves applying mechanical pressure to create a gas-tight connection.

-

Bi-Metal Cable Lugs-DTL

Bi-Metal Cable Lugs-DTL● Bimetallic Construction: Bi-metal cable lugs are constructed with two different metals, usually copper and aluminum, joined together. The copper part is designed to make a secure connection with copper conductors, while the aluminum part is designed to connect to aluminum conductors.

● Types: Bi-metal cable lugs come in various types and configurations to accommodate specific applications. They may include compression-type lugs, bolted lugs, or other connection methods.

● Transition: These lugs allow for a smooth and secure transition between copper and aluminum conductors without the risk of galvanic corrosion. This is important because copper and aluminum have different electrical and mechanical properties.

● Termination: They can be crimped or bolted onto the respective copper and aluminum conductors. Crimping ensures a gas-tight and reliable connection, while bolting provides a mechanical connection.

-

Copper Aluminum Cable lugs-CAL-A

Copper Aluminum Cable lugs-CAL-A● Bimetallic Construction: Bi-metal cable lugs are constructed with two different metals, usually copper and aluminum, joined together. The copper part is designed to make a secure connection with copper conductors, while the aluminum part is designed to connect to aluminum conductors.

● Types: Bi-metal cable lugs come in various types and configurations to accommodate specific applications. They may include compression-type lugs, bolted lugs, or other connection methods.

● Transition: These lugs allow for a smooth and secure transition between copper and aluminum conductors without the risk of galvanic corrosion. This is important because copper and aluminum have different electrical and mechanical properties.

● Termination: They can be crimped or bolted onto the respective copper and aluminum conductors. Crimping ensures a gas-tight and reliable connection, while bolting provides a mechanical connection.

-

Copper Aluminum Cable lugs-CAL-B

Copper Aluminum Cable lugs-CAL-B● Bimetallic Construction: Bi-metal cable lugs are constructed with two different metals, usually copper and aluminum, joined together. The copper part is designed to make a secure connection with copper conductors, while the aluminum part is designed to connect to aluminum conductors.

● Types: Bi-metal cable lugs come in various types and configurations to accommodate specific applications. They may include compression-type lugs, bolted lugs, or other connection methods.

● Transition: These lugs allow for a smooth and secure transition between copper and aluminum conductors without the risk of galvanic corrosion. This is important because copper and aluminum have different electrical and mechanical properties.

● Termination: They can be crimped or bolted onto the respective copper and aluminum conductors. Crimping ensures a gas-tight and reliable connection, while bolting provides a mechanical connection.

-

Copper Aluminum Cable lugs-European style

Copper Aluminum Cable lugs-European style● Bimetallic Construction: Bi-metal cable lugs are constructed with two different metals, usually copper and aluminum, joined together. The copper part is designed to make a secure connection with copper conductors, while the aluminum part is designed to connect to aluminum conductors.

● Types: Bi-metal cable lugs come in various types and configurations to accommodate specific applications. They may include compression-type lugs, bolted lugs, or other connection methods.

● Transition: These lugs allow for a smooth and secure transition between copper and aluminum conductors without the risk of galvanic corrosion. This is important because copper and aluminum have different electrical and mechanical properties.

● Termination: They can be crimped or bolted onto the respective copper and aluminum conductors. Crimping ensures a gas-tight and reliable connection, while bolting provides a mechanical connection.

-

Copper Aluminum Cable lugs-For cable tap box

Copper Aluminum Cable lugs-For cable tap box● Bimetallic Construction: Bi-metal cable lugs are constructed with two different metals, usually copper and aluminum, joined together. The copper part is designed to make a secure connection with copper conductors, while the aluminum part is designed to connect to aluminum conductors.

● Types: Bi-metal cable lugs come in various types and configurations to accommodate specific applications. They may include compression-type lugs, bolted lugs, or other connection methods.

● Transition: These lugs allow for a smooth and secure transition between copper and aluminum conductors without the risk of galvanic corrosion. This is important because copper and aluminum have different electrical and mechanical properties.

● Termination: They can be crimped or bolted onto the respective copper and aluminum conductors. Crimping ensures a gas-tight and reliable connection, while bolting provides a mechanical connection.

-

Copper Cable Lugs-OT

Copper Cable Lugs-OT● Material: Copper cable lugs marked as "OT" are made from high-conductivity copper or copper alloy, which provides excellent electrical conductivity and mechanical strength.

● Types: Copper cable lugs are available in various types, including ring lugs, spade lugs, pin lugs, and butt splice lugs, each designed for specific applications and connection methods.

● Sizing: They come in different sizes, with the "OT" marking typically indicating the lug's size or wire capacity, ensuring compatibility with a range of conductor diameters.

● Termination: Copper cable lugs are typically crimped onto the copper conductor using a specialized crimping tool. The crimping process involves applying mechanical pressure to create a gas-tight connection.

Sorry, no matches were found in Products for Cable lug.

Want to get the matched products and detailed quotations?

+86-25-58065309

+86-25-58065309

www.sohogroup.cn

www.sohogroup.cn Daqiao Industry Park, Yangzhou City,

Daqiao Industry Park, Yangzhou City,