Categories

- TRANSMISSION-LINE

- Transmission-Line Fittings

- String Hardware

- Tower Attachment

- Parallel Groove Clamp

- Suspension Clamps

- Tension Clamps

- Compression Joint

- Repair Sleeve

- Preformed Armour Rod

- Stockbridge Damper

- Spacer & Spacer Damper

- Arcing Devices

- Counterweight & Jumper weight

- Danger plate & Number plate

- Corona & Grading Rings

- Transmission Conductor

- All aluminium stranded conductors(AAC)

- Aluminium conductors steel reinforced(ACSR)

- All aluminium alloy conductors(AAAC)

- Aluminium alloy conductors steel reinforced(AACSR)

- Arial Earth Wire & Shield Wire & Galvanized Steel Wire

- Porcelain Disc Suspension Insulators

- Composite Long Rod Insulators

- Toughened Glass Disc Insulator

- Tower of Transmission-Line

- SUBSTATION

- Connector and Fittings for Tubular Busbar

- Tubular Busbar Palm(Welding)

- Busbar A-Frame

- Connector for Tubular Busbar

- Tubular Busbar Support

- Tubular Busbar Earthing

- Tubular Busbar End Caps & Balls

- Substation Insulators

- Solid Porcelain Post Insulators(66kV -500kV)

- Solid Polymer Post Insulators(66kV-500kV)

- Hollow Core Insulators for Voltage Transformer

- Hollow Core Insulators for Capacitor

- Porcelain Disc Insualtors

- Polymer Long Rod Insulators

- Glass Disc Insulators

- Busbar

- Tubular Copper Busbar

- Rectangular Aluminum Busbar

- Rectangular Copper Busbar

- Tubular Aluminum Busbar

- Terminations & Connections for Conductor

- Aluminium Flexible Connector

- Copper Flexible Connector(Flat Braid)

- Compression Run Compression T Clamp(Closed)

- Compression Run Compression T Clamp(Open)

- Compression Run Palm Tap(Closed)

- Compression Run Palm Tap(Open)

- Compression Terminal Clamp

- Twin Conductor Compression Terminal Clamp

- Straight Bolted Type Terminal Clamp

- 90° Bolted Type Terminal Clamp

- Straight Twin Conductor Bolted Type Terminal Clamp

- 90° Twin Conductor Bolted Type Terminal Clamp

- Twin Conductor Bolted Type Tee Clamp

- Twin Conductor Run Palm Tap Lengthways Terminal Clamp

- Twin Conductor Run Palm Tap Transverse Terminal Clamp

- Parallel Groove Clamp

- Straight Connector Conductor to Conductor

- Tee Connector Conductor to Conductor

- Adaptor Plates

- Straight Type

- Right Angle Horizontal Type

- Right Angle Vertical Type

- Bi-Metallic Transition Plate

- Spacers

- Galvanized & Stainless Steel Bolts Assemblies

- Strings Fittings

- Connections for Flat Busbar

- Gantries & Structure

- Distribution Conductor

- All Aluminium Stranded Conductors(AAC)

- All Aluminium Alloy Conductors(AAAC)

- Substation Parallel Spacer Triple

- DISTRIBUTION

- Preformed Fittings

- Armor-Grip Suspension Clamp

- Trunnion Armor-Grip Clamp

- Aluminum Alloy Dead-Ends

- Copper Alloy Dead-End

- Thimbles

- Top Ties

- Armored Rod Twin Ties

- Side & Spool Ties

- Parrot Bill End Aluminum Alloy Armor Rods

- Copper Alloy Armor Rods

- Galvanized Steel Armor Rods

- Aluminium Alloy Line Splice

- Copper Alloy Line Splices

- Galvanized Steel Line Splices

- Aluminium Alloy Full Tension Line Splice

- T-Connector

- Helical Arcing Horn

- Galvanized Steel Guy-Grip

- Pole Top Make Off

- Insulated Stay

- Double-Wrap Guy-Grip

- Spiral Vibration Damper High Impact PVC

- Lashing Rods

- PVC Spacer

- The Pole Line Hardware

- Cross Arms

- Fastenes Bolts & Nuts

- Thimble Bolt Rod & Eye Bolt

- Eye Nuts

- Clevis

- Insulation Pin & Studs & Spindles

- Pole Hoop

- Cable & Conductor

- ACSR

- AAC

- ABC Cable

- SAC Cable

- Distribution Insulators

- Porcelain Disc Insualtors

- Polymer Long Rod Insulators

- Glass Disc Insulators

- Porcelain Line Post Insulators(Vertical)

- Porcelain Line Post Insulators(Horizontal)

- Polymer Line Post Insulators(Vertical)

- Polymer Line Post Insulators(Horizontal)

- Porcelain Pin Insulator(BS standard)

- Porcelain Pin Insulator(ANSI standard)

- Polymer Pin Insulators

- Shackle Insulators

- Spool Insulators

- Stay Insulators

- Wiring Insulators

- Telephone Lines Insulators

- Guy Strain Insulators

- Spindle for insulators

- BS Spindle for Pin Insulators

- ANSI Spindle for Pin Insulators

- Normal Short Spindle for Line Post Insulators

- Rachet short spindle for line post insulators

- Rachet long spindle for line post insulators

- Fuse/fuse cutout

- Porcelain Fuse Cutout

- Composite Fuse Cutout

- K Type Fuse Link

- HRC Fuse

- J Type Fuse

- Disconnect Switch

- Surge Arrestor 11-36kV(5kA-10kA)

- Over head Line fittings

- Suspension Clamp

- Bolt Type Tensioning Clamp

- U-Bolts

- Shackle

- Ball Eye

- Socket Tongue

- Arcing Horn

- UT Connectors

- ABC fittings

- Copper Strand Wire and Braid Connector

- Insulation Piercing Connector(IPC)

- Fire-Retardant IPC

- T connecting Terminal

- Insulation Piercing Grounding Connectors

- Fuse Bace

- Wedged Insulation Strain Clamp

- Suspension Clamp for ABC cable

- Suspension Clamp with Aluminum Bracket

- Anchoring Clamp

- Metal Anchor Clamp

- Four-Core Tension Clamp

- Pre-Insulated Sleeve

- Pre-Insulated Bimetal Sleave

- Expansion Screws

- JXL Series Clamp(Wedge Type)

- Parallel Groove Clamp with Insulator Cover

- SAC fittings

- Anti Sway Bracket for HDPE Spacer

- Tangent Support Bracket

- HT Tape for SAC Cable

- Cable lug

- Copper Cable Lugs-DT

- Double Holes Copper Cable lugs-DT2

- Aluminum Cable Lugs-DL

- Double holes Aluminum Cable lugs-DL2

- Bi-Metal Cable Lugs-DTL

- Copper Aluminum Cable lugs-CAL-A

- Copper Aluminum Cable lugs-CAL-B

- Copper Aluminum Cable lugs-European style

- Copper Aluminum Cable lugs-For cable tap box

- Copper Cable Lugs-OT

- P.G. Clamp & Connector

- Copper Parallel Groove Clamp-CAPG

- Aluminum Parallel Groove Clamp-CAPG

- Copper Parallel Groove Clamp

- Aluminum Parallel Groove Clamp-JB

- Copper-Aluminum Parallel Groove Clamp-CAPG(Hard-Solder)

- Copper-Aluminum Parallel Groove Clamp-CAPG( Friction Welding)

- C Clamp-Copper

- C Clamp-Aluminum

- Connecting Clamp-Aluminum

- Connecting Clamp-Copper

- Connecting Clamp (Hard-Solder)

- Connecting Clamp (Friction Welding)

- Connecting Tube-Aluminum

- Connecting Tube-Copper

- Connecting Tube-Bimetal

- Copper Plate

- Aluminum Plate

- Bimetal Plate

- Copper-Aluminum Parallel Groove Clamp( Friction Welding)

- Stay complete set

- Eye Bolts

- Turn Buckle

- Thimble

- Stay Grip

- Stay Wire

- Adjustable Stay Rod

- Non Adjustable Stay Rod

- Stay Anchor Plate/Earth Plate

- Other accessory

- Stainless Steel with Retaining Buckle

- Cable Nail

- Insulation Tape

- Stainless Steel Strip

- Aluminium Insulated Tie Wire

- COMMUNICATION

- Dead-End for OPGW

- Single Suspension Set

- Double Suspension Set

- Vibration Damper

- Armour Rods for Vibration Damper

- Ground Wire Set

- Joint Box

- Cable Tray

- Spiral Vibration Damper

- Corona Coil

- Downlead

- Downlead

- Fastened Fittings for Pole

- Fastened Fittings for Pole

- Fastened Fittings for Twoer

- Fastened Fittings for Twoer

- Fastened Fittings for Twoer

- GROUNDING SYSTEM

- Earth Rod

- Solid Stainless Steel Earth Rods

- Solid Copper Earth Rods

- Copper Clad Steel Earth Rods

- H.D.G Steel Earth Rods

- Earthing Wire

- Copper Wire

- PVC Covered Copper Wire

- Flexible Copper Braid

- Copper Clad Steel Wire

- Fittings for Earth Rod

- Fittings for Threaded Earth Rod

- Fittings for Unthreaded Earth Rods

- Earth Tube

- Conductor Tape

- Copper Tape

- Tinned Copper Tape

- PVC Insulated Copper Tape

- Stainless Steel Tape

- Aluminum Tape

- Bentonite

- Concrete Earth Pits

- Connectors

- C connectors

- Tinned Copper Flexible Connector

- Tape Clip

- Tape Clamp

- Rod to Tape Clamp

- Rod to Cable Clamp

- U-Bolt Rod Clamp

- Earth Points

- Earth Plates

- Solid Copper Earth Plates

- Lattice Copper Earth Plates

- Earth Bars & Disconnector Links

- Exothermic Welding

- Exothermic Powder

- Tooling Box

- Exothermic Welding Mould

- Marconite

- INSULATOR FITTINGS

- Clevis Fittings

- Y-Clevis Fittings

- Tongue Fittings

- Socket Fittings

- Ball Fittings

- Eye Fittings

- For Line Post Insulator

- For Cross-Arm Composite Insulator

- For Pin Insulator

- For Railway Insulator

- For Clamp (Vertical)

- For Clamp (Horizontal)

- Ball Pin & Socket Cap

- Tongue Pin & Clevis Cap

- For Others

- Top Head Fitting for Line Post Insulator

- Top Head Fitting Clevis for Line Post Insulator

- Top Head fitting Tongue for Line Post Insulator

- POWER CONSTRUCTION TOOLS

- Galvanized Steel Antitwist Wire Rope

- Hydraulic Press

- Hand Hydraulic Crimping Tools

- Cable Cutter

- Tube Terminal Crimping Tools

- Mechanical Cable Cutter

- Wire Grip

- Hand Puller

- Snactch Block

- Stringing Block

- Cable Wellhead Pulley

- Cable Orifice Protection Pulleys

- High Voltage Operating Rod/Hot Stick

- H.V. Earthing Wire and Rod

- Security Clamp

- Wood Pole Climber

- Grounding Clamp

- Hot Line Cable Clamp

- Swivel Joints

- Elelctro Scope

- OEM/ODM

- SOLAR

Over head Line fittings

Over head Line fittings

-

Suspension Clamp

Suspension ClampFor standard voltage application with all aluminum conductors, aluminum alloy conductors, aluminium conductor steel reinforced, aluminium alloy conductor steel reinforced with/without formed armor rod or armor tape. Also application with galvanized steel strand wire and aluminum clad steel strand wire.

Material:

Body – aluminum alloy

Keeper – aluminum alloy

Hardware – hot dip galvanized steel (ISO1461,ASTM A153)

Cotter pin – stainless steel

-

Bolt Type Tensioning Clamp

Bolt Type Tensioning ClampFor standard voltage application with all aluminum conductors, aluminum alloy conductors, aluminium conductor steel reinforced, aluminium alloy conductor steel reinforced. Also application with galvanized steel strand wire and aluminum clad steel strand wire.

Material:

Body – aluminum alloy

Keeper – aluminum alloy

Hardware – hot dip galvanized steel (ISO1461,ASTM A153)

Cotter pin – stainless steel

-

-

-

-

Socket Tongue

Socket TongueVertical ultimate strength - 40kN-600kN with various models

Material - Forged steel

Heat treatment - Hardening and Tempering

Finish - Hot dip galvanized (ISO1461,ASTM A153)

Packing - Wooden case

Standard reference - IEC61284

-

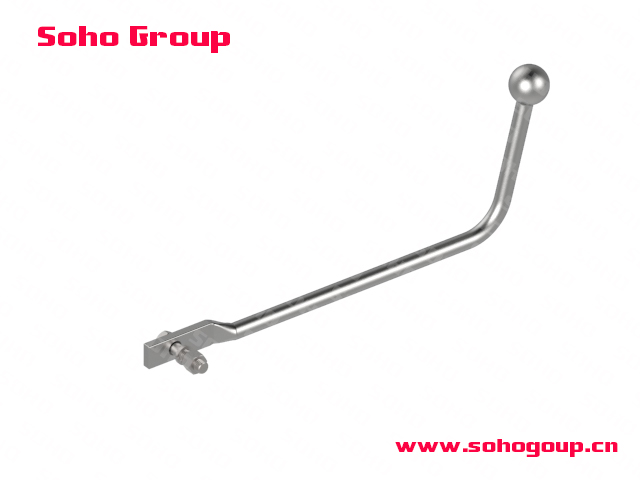

Arcing Horn

Arcing Horn● Arc Mitigation: The primary purpose of an arcing horn is to mitigate the effects of electrical arcing, which can generate high temperatures and potentially damage or degrade nearby equipment or insulators.

● Split Ring Design: Arcing horns have a distinctive split ring or U-shaped design, which is typically mounted around the fittings or insulators. This design helps to redirect and disperse the arc flash that may occur.

● Materials: Arcing horns are typically made of materials with good electrical conductivity and mechanical strength, such as aluminum or other non-ferrous alloys.

● Mounting: They are mounted around the fittings or insulators and are secured in place. The presence of arcing horns can be an integral part of the overall design and safety measures in high-voltage systems.

● Electrical Safety: Arcing horns improve electrical safety by redirecting and dissipating the energy associated with an arc flash, reducing the risk of damage to equipment, insulators, or other components in the vicinity.

● Application: These horns are commonly used in high-voltage applications, such as substations, transmission lines, and other locations where the risk of electrical arcing is significant.

-

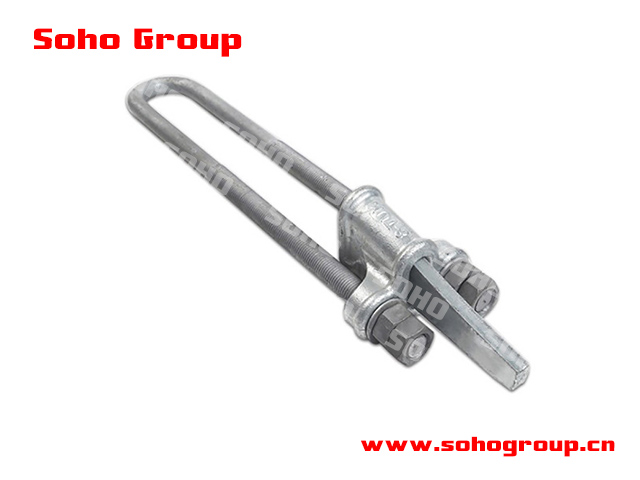

UT Connectors

UT Connectors● Types of UT Clamps: UT clamps come in various types and designs, each suited to a specific application. They may be used for conductor support, grounding, splicing, dead-ending, or connecting various components in power line systems.

● Materials: UT clamps are typically constructed from materials such as aluminum, steel, or other non-ferrous alloys to ensure durability and resistance to environmental conditions.

● Design: The design of UT clamps varies depending on their intended use. They may feature bolts, wedges, or other mechanisms for securing conductors or components.

● Installation: The installation of UT clamps usually involves attaching them to supporting structures like utility poles, towers, or crossarms. They secure conductors and components in place to maintain electrical connections, mechanical stability, and appropriate tension.

● Tension Relief: UT clamps can be used for relieving mechanical tension or stress on power lines. This helps prevent conductor sagging, reducing the risk of electrical faults and maintaining proper clearances.

● Corrosion Resistance: Many UT clamps are designed to be corrosion-resistant and weatherproof, ensuring their long-term performance in outdoor environments.

● Code Compliance: The selection and installation of UT clamps should adhere to local electrical codes, regulations, and industry standards to ensure safety and reliability in power distribution systems.

● Safety: UT clamps play a critical role in enhancing the safety and reliability of overhead power distribution and transmission systems. They prevent conductor movement, secure components, and support electrical connections.

Sorry, no matches were found in Products for Over head Line fittings.

Want to get the matched products and detailed quotations?

+86-25-58065309

+86-25-58065309

www.sohogroup.cn

www.sohogroup.cn Daqiao Industry Park, Yangzhou City,

Daqiao Industry Park, Yangzhou City,